Special belts

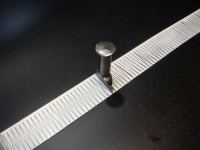

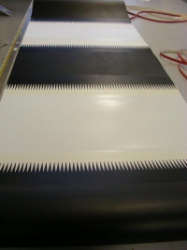

Belts from the "MF" seamless rubber

Reko Ltd offers a broad scale of various belt types that are applicable in different industrial branches (e.g., packaging, paper-and-pulp, cardboard industry, services etc.).

MF belts properties:

without any fasting processes: all belts are manufactured seamless by a special technology so as to guarantee a regular surface along the whole length, having a uniform friction factor on the whole belt surface,

without any fasting processes: all belts are manufactured seamless by a special technology so as to guarantee a regular surface along the whole length, having a uniform friction factor on the whole belt surface,

absolutely even thickness,

absolutely even thickness,

polyester-made tractive body provides for an excellent size durability and high tensile strength.

polyester-made tractive body provides for an excellent size durability and high tensile strength.

Rubber coat is colour-differentiated according to the friction and hardness factor:

L raspberry colour, 35 ° Sh.A

R raspberry colour, 35 ° Sh.A

B raspberry colour, 35 ° Sh.A

HS raspberry colour, 35 ° Sh.A

Maximal thickness: 15 mm with the abraded plane.

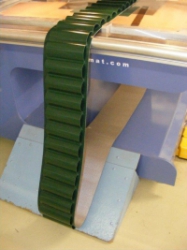

When used in a synchronized shift, the belts with module gear can be applied. When it is requested, also the perforated belt can be supplied to be used on the air-suction machine.

Belts for continuous sanders (woodworking)

These belts were developed for the above-mentioned purpose. They include 2 up to 3 layers of highly solid polyester textile fabric (PES) as well as the work-layers of a special highly abrasion-resistant rubber. Rubber work-surface can be plane or markedly tread-profiled, eventually vented for vacuum holding-up.

Belts for paper-and-pulp industry

Seamless belts are used as the ingoing and guiding belts for the sawing-out and glueing machines, including all the machines of paper-and-pulp industry. Due to its innner rubber layering, the MF-351 G type is designated namely for the high-speed sawing-out and glueing machines where the constant speed is guaranteed. Available are belts in the two various hardnesses (MF layers) dependent on a type of processed cardboard; in order to achieve a compromise between friction and wearing, we offer:

- 35 °ShA raspberry colour: the processing of a light cardboard.

- 45 °ShA raspberry colour: the processing of corrugated cardboard and various harnder tensioned cardboards.

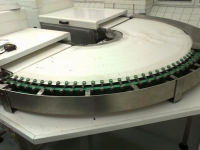

Belts for packing and dosing machines

Belts for packing and dosing machines: especially for the food processing industry. They work in pairs having an important task so as to ensure a precise and correct shifting during the filling of pokes with the individual components (candies, potatoe chipses, ...). These belts function perfectly at 80-150 cycles/min. Available are the three types of belts with differentiated MF hardness layers dependent on a type of processed goods; in order to achieve the best compromise between friction and wearing, we offer:

- 35 °ShA raspberry colour: for slippy packing materials, e.g.: polyethylen and PVC-foil.

- 45 °ShA red colour: suitable namely for coarse materials (paper, textile fabric).

- 50 °ShA beige colour: suitable namely for rough materials (paper, textile fabric).